Our state of the art methods can be used to cut most any design out of soft flexible non metallic materials as well as some harder and more rigid substrates.

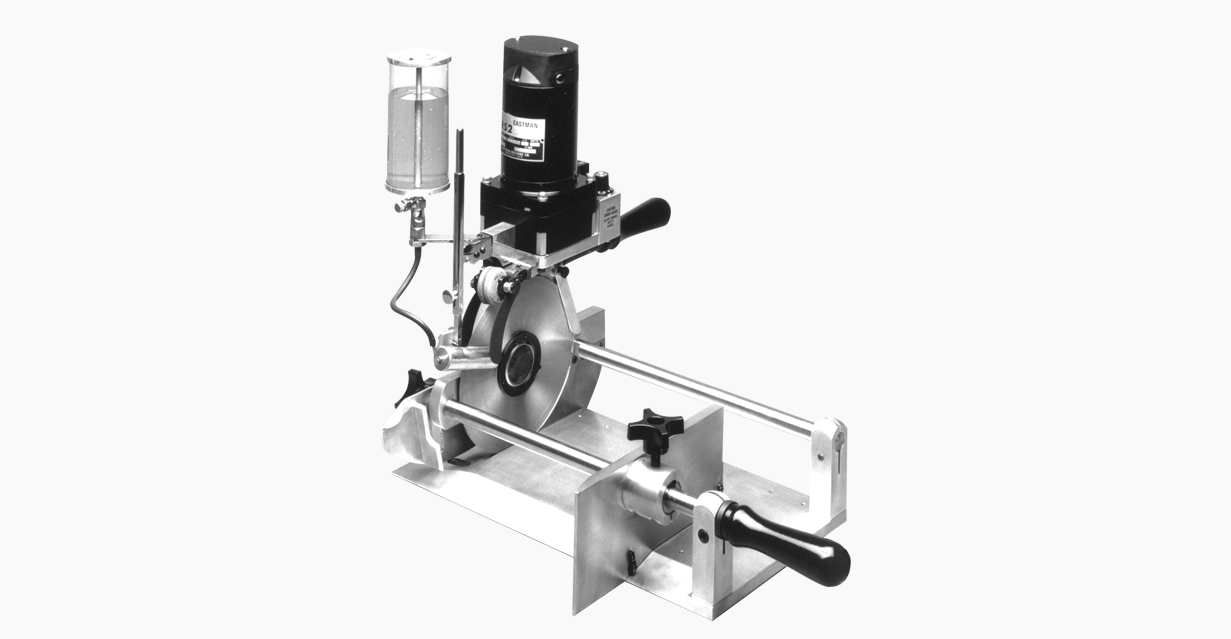

Rubber sheet cutting table.

The best solution to cut table tennis rubber.

Also cutting many different rubber pvc gask.

This helps to protect your rubber.

These punching tables are ideal for quickly punching holes in gaskets washers and shims from compressed sheet rubber fiber oil paper brass copper and more.

The rubber manufacturers association rma has developed tolerance tables with ranges to provide communication between user and provider across a wide range of industries.

You can also consult the rma article on factors affecting tolerances of molded rubber products.

The overall dimension of the rubber part must also be relatively small and less than 24 inches on any one side.

The top countries of suppliers are china taiwan china and india from which the percentage of rubber sheet cutting machine supply is 99 1 and 1 respectively.

This style is limited to thinner sheets of rubber.

Use the rubber chip to remove the residual glue on the blade and on the old rubber.

Peel off the rubber.

Too much heat will quickly bake the rubber and turn into into a sheet of antispin while too much cold will make the rubber more brittle and kill the spring in the sponge so don t leave your ping pong paddle sitting in the sun on the dashboard of your car.

Atlantic gasket uses the molded tolerances per the graduated tables below.

Soft rubber sheet cutting machine aol oscillatory knife cutting table this machine can cut 40mm rubber materials.

Generally sheets thicker than 3 8 inch 375 cannot be die cut.

So if you are the owner of a table tennis shop or a club manager or a table tennis coach that you need to glue to cut many many rubbers for your players i would recommend you to buy these electric scissors.

And peel it from the side of the blade.

The gasket punch table easy hole punching.

Rma provides different tables for molded and die cut rubber parts.

Designed to be easy to use and maintain fabricated from heavy duty steel.

It will save you a lot of time and efforts.

To peel off the old rubber you should do it slowly.

You can cut a small piece of unused rubber and use it as the rubber chip.

Final note be wary of temperature extremes table tennis rubbers don t like extremes of heat or cold.

Die cutting cannot be performed with just any material and thickness.

These are helpful when designing and producing a part.

Luckily the rubber manufacturer s association has developed a range of tolerances and published it in their rma rubber handbook the most recent of which is the 2005 version.

.png)